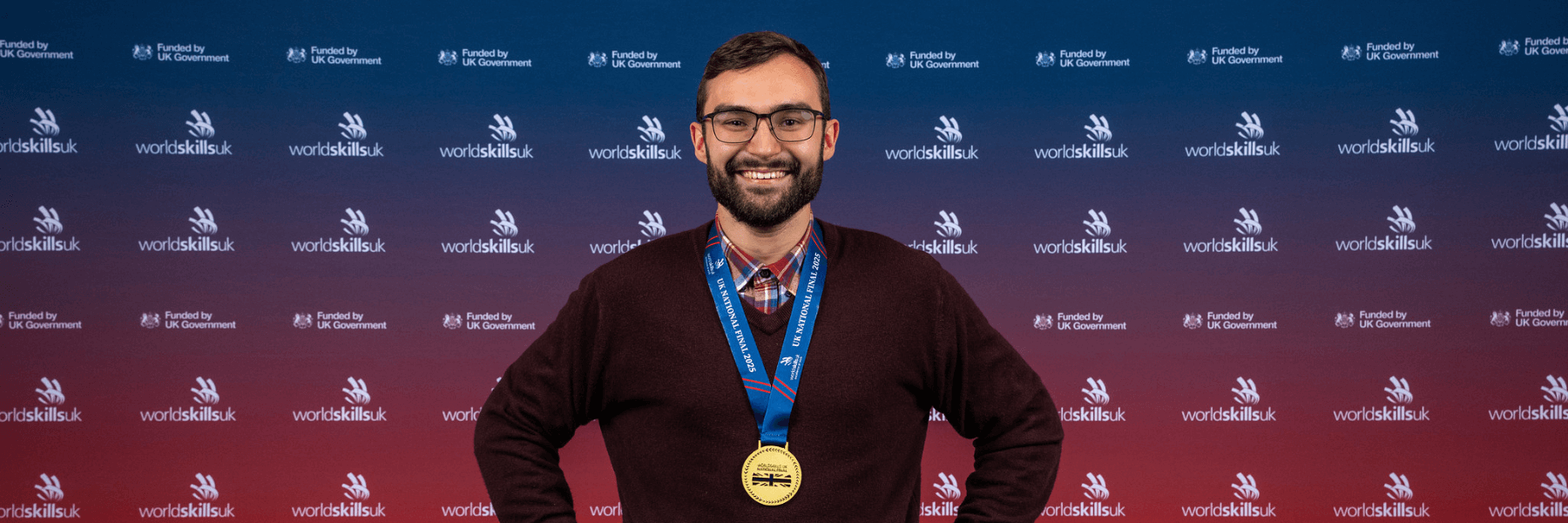

Marc’s passion for the automotive world shines through in everything he does

Marc is an absolute credit to our team and someone we all hold in very high regard. He’s knowledgeable, accurate, and takes real pride in everything he does, no matter how big or small the job, he approaches it with the same enthusiasm and care. You can always rely on Marc to get things right, but also to do them in the right way.

What really stands out about Marc is his genuine character. He’s kind, patient, and always willing to make time for others. Whether that’s helping a colleague, answering questions, or just lifting the mood in the workshop.

His passion for the automotive world shines through in everything he does, and his drive to keep learning and improving is something we all admire. Marc is thoughtful and analytical in his approach, always considering every option before making a decision. He’s loyal, hardworking, and completely dedicated to both his craft and his team. We honestly can’t imagine the place without him. He’s not only a talented apprentice but also a genuinely great person to work alongside. I genuinely believe we couldn’t do what we do without him.

Our apprentice teams are supported in a blended learning platform. The team members will spend week blocks in our brand dedicated learning facility being upskilled in both theoretical and practical learning with our brand training experts at the NLC. Back in the workshop, we have a highly skilled team of technicians all with brand accreditations. These are a carefully selected team of highly skilled and motivated technicians who work together as a team extremely well.

Our technicians understand fully the importance of bringing young talent through our workshop and sharing their skill with these young adults. We have also seen in most recent years, the apprentices sharing back to their mentors new skills and methods they have learned from the training blocks. This is a really organic and collaborative way of learning and sharing that we feel strengthens their working relationships.

Our workshop also utilises the existing talent across our entire workshop by rotating our mentors throughout their programme, we rotate roughly every 8 weeks. We have found this practice gives the candidate the ability to learn different skills and methods in vehicle maintenance and repair. It also promotes positive working relationships within the team, it is inclusive, fair and diverse. This way ensures all team members have the responsibility and benefits of working alongside our apprentices.

Lastly, we’re very proud of our internal Apprentice Development Programme, every year we take out our whole cohort of apprentices from the business and host “development days”, usually a morning full of networking and learning, and usually an afternoon of fun riding rollercoasters or racing around go-kart tracks! The days receive incredible feedback and really enhances our programme.

Over the next decade, I believe the light commercial vehicle sector will transform more dramatically than at any other point in our lifetime. Electric vans will take centre stage, not just because of government pledges, but because they’ll simply make sense for businesses. Lower running costs, improved reliability, and continued advances in battery range will make electric the default choice for most fleets. Diesel and hydrogen will still have a place in certain long-distance or heavy-load operations, but the everyday van will be electric, connected, and much smarter than what we see on the road today.

What really strikes me is how much this change will impact the people behind the scenes, especially our technicians. The traditional toolbox will evolve; high-voltage systems, software diagnostics, and data-driven maintenance will become part of everyday work. AI will play a major role here too, supporting predictive maintenance, fault diagnosis, and even remote repair guidance. Workshops will become more like technical hubs, combining engineering skill with digital insight, and technicians will need new training and confidence to thrive in this environment.

AI will also reshape how fleets are managed and how vehicles are built. From smart route optimisation and automated scheduling to self-learning production systems in manufacturing, artificial intelligence will drive efficiency at every stage of the vehicle’s life. By the early 2030s, I see fleets running quietly and intelligently through cities. Electric, data-connected, and supported by people and systems working in harmony. The future van won’t just move goods; it’ll be part of a living, learning network that brings together technology, sustainability, and human expertise.